The assurance of purity, precision and consistency in custom mixing

Industries need mixed rubber stock with the highest purity standards for their products. Compound precision, consistency and repeatability are critical for the final product. We specialize in custom rubber mixing for products that require clean, contamination-free mixed rubber stock.

The right mix is critical. Our mixing process meets the highest quality and purity standards whether your products are in Medical, Belting, Hose, Pharma, Specialty Industrial applications or others. Our customers in all industries rely on us to provide polymeric compounds and products for their most critical applications.

Our facilities utilize unique state-of-the-art process control and quality systems.

Materials

Natural Rubber, Synthetic Polyisoprene

Styrene Butadiene Rubber, Nitrile, Butyl and moreProduct Applications

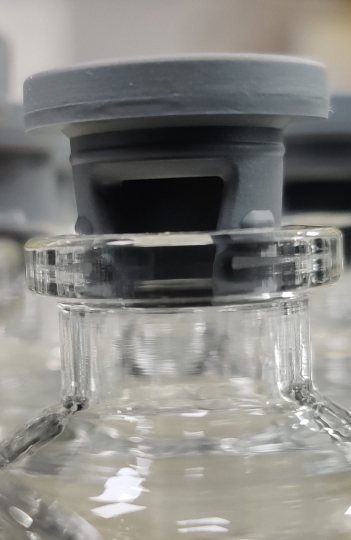

Hoses, Gaskets, Rubber seals and Stoppers, Rubber Convertible Tops and moreFeatures & Benefits

Compound precision

Consistency, and purity, at the highest industry standards

No mixing of free carbon black

Provide color-match requirements, master-batch, and full cure mixed stock

Stringent change control standard

Extrude and screen your rubber compound up to 300-mesh, delivering ultra-clean material

With operations in the US and India, we are globally positioned to serve both existing and emerging needs for high-quality custom mixing solutions.

GET IN TOUCHCustom rubber mixing

Contamination-free, precise and consistent compound rubber mixing for your applications in medical, industrial, automotive and many more markets.